Zaus conversion ceev regulating magnetic polishing tshuab

Khoom Qhia

Technical parameter

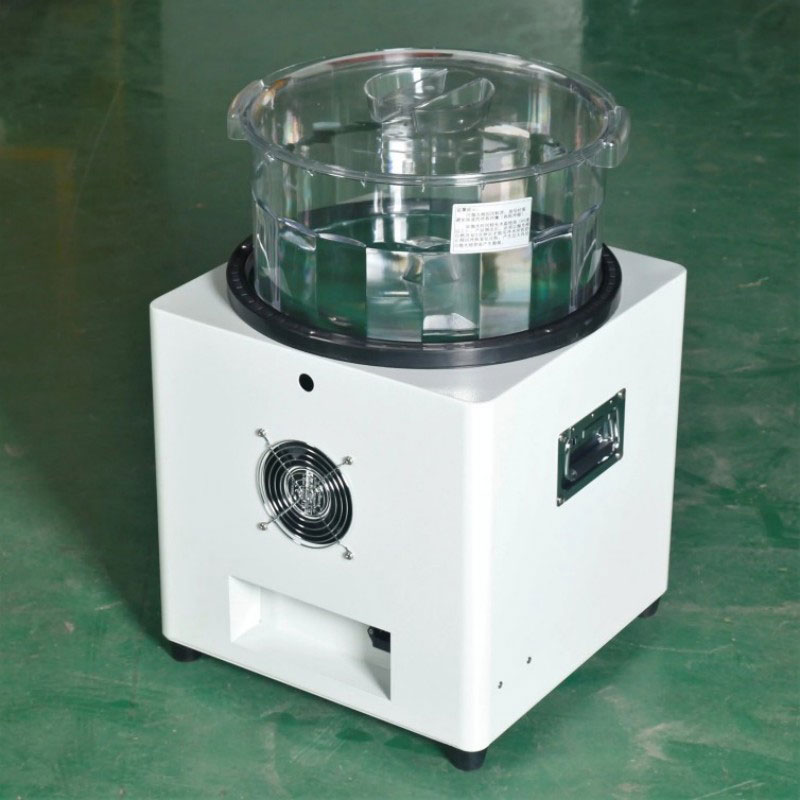

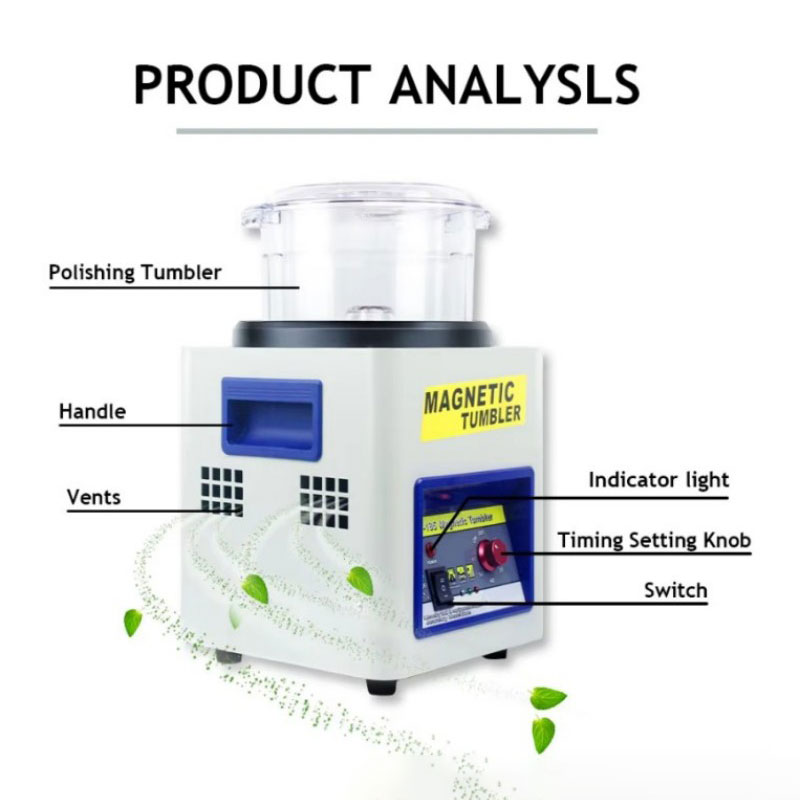

| Khoom npe | 5KG magnetic quab yuam tshuab | Polishing hnyav | 5 KG |

| Qhov hluav taws xob | 220 V | Polishing koob tshuaj | 0-1000g |

| Ceev feeb | 0-1800 R / MIN | Hwj chim | 1.5 KW TSI |

| Tshuab hnyav | 60 KG | Qhov Loj (mm) | 490 * 480 * 750 hli |

| Daim ntawv pov thawj | CE, ISO9001 | Txias qhov system | Cua txias |

| Hom kev ua haujlwm | Tsis tu ncua | Feature | Kev saib xyuas tsawg |

| Machinery Test Report | Muab | Kev tshuaj xyuas video tawm | Muab |

| Qhov Chaw Keeb Kwm | Jinan, Shandong xeev | Lub sijhawm lav | 1 xyoo |

Tshuab Video

Tus yam ntxwv ntawm zaus hloov pauv ceev tswj kev sib nqus polishing tshuab

1. Kev tswj hwm kev hloov pauv ceev: qhov ceev tuaj yeem hloov kho raws li kev ua haujlwm sib txawv los txhim kho kev ua haujlwm raug thiab ruaj khov;

2. Kev ua haujlwm siab: ntau cov khoom me me tuaj yeem ua tiav tib lub sijhawm, thiab qhov ua tau zoo yog ntau dua li phau ntawv lossis tsoos nruas polishing;

3. Tsis muaj lub kaum sab xis ua tiav: rab koob sib nqus tuaj yeem nkag mus rau hauv lub qhov, seams, grooves thiab lwm yam haujlwm me me ntawm cov khoom ua haujlwm kom ua tiav txhua yam polishing;

4. Kev tiv thaiv ib puag ncig thiab txuag hluav taws xob: tsis siv cov kua tshuaj corrosive, tsis tshua muaj suab nrov, ua haujlwm yooj yim;

5. Tsawg tus nqi tu: cov cuab yeej muaj cov qauv yooj yim, ruaj khov, thiab yooj yim txij nkawm txhua hnub;

6. Kev ua haujlwm zoo sib xws: qhov sib xws ntawm cov khoom ua haujlwm yog siab, uas yog tsim rau ntau lawm.

Kev pabcuam

1. Cov kev pabcuam customized:

Peb muab customized Frequency conversion ceev regulating magnetic polishing tshuab, kev cai tsim thiab manufactured raws li cov neeg xav tau kev pab. Peb tuaj yeem kho thiab kho nws raws li cov neeg siv khoom tshwj xeeb.

2. Kev sib tham ua ntej muag thiab kev txhawb nqa:

Peb muaj ib pab neeg ua haujlwm paub txog uas tuaj yeem muab cov neeg siv khoom nrog cov lus qhia ua ntej muag thiab kev txhawb nqa. Txawm hais tias nws yog kev xaiv cov cuab yeej siv, cov lus qhia hauv daim ntawv thov lossis kev qhia, peb tuaj yeem muab kev pab sai thiab ua tau zoo.

3. Cov lus teb sai tom qab muag

Muab kev txhawb nqa sai tom qab kev muag khoom los daws ntau yam teeb meem ntsib los ntawm cov neeg siv khoom thaum siv.

FAQ

Q: Cov ntaub ntawv dab tsi haum rau lub tshuab sib nqus polishing?

A: Lub tshuab sib nqus polishing yog tsim rau cov khoom siv hlau xws li stainless hlau, tooj liab, txhuas, titanium alloy, thiab tseem tuaj yeem ua qee cov yas ua haujlwm nyuaj.

Q: Lub workpiece loj npaum li cas tuaj yeem ua tiav?

A: Lub tshuab magnetic polishing yog tsim rau kev ua cov khoom me me, qhov tseeb (feem ntau tsis loj dua qhov loj ntawm lub xib teg), xws li screws, springs, rings, electronic accessories, etc. Workpieces uas loj dhau tsis haum rau cov koob sib nqus nkag. Nws raug nquahu kom siv lwm yam khoom siv xws li nruas polishing tshuab.

Q: Nws puas tuaj yeem polished rau hauv qhov lossis grooves?

A: Yog. Cov koob hlau nplaum tuaj yeem nkag mus rau hauv lub qhov, slits, qhov muag tsis pom kev thiab lwm qhov chaw ntawm lub workpiece rau txhua qhov polishing thiab deburring.

Q: Lub sijhawm ua haujlwm ntev npaum li cas?

A: Nyob ntawm cov khoom ntawm lub workpiece thiab cov degree ntawm nto roughness, lub sij hawm ua feem ntau adjustable los ntawm 5 mus rau 30 feeb. Kev tswj hwm kev hloov pauv ceev ceev tuaj yeem ua tiav cov txiaj ntsig ua tau zoo dua.

Q: Puas tsim nyog ntxiv cov kua tshuaj?

A: Tsis tas yuav tsum muaj cov kua tshuaj corrosive. Feem ntau, tsuas yog dej huv thiab me me ntawm cov kua tshwj xeeb polishing yog xav tau. Nws yog ib puag ncig tus phooj ywg, nyab xeeb thiab yooj yim tawm.

Q: Puas yog rab koob sib nqus yooj yim hnav? Lub neej ua haujlwm ntev npaum li cas?

A: Cov koob sib nqus yog ua los ntawm cov hlau muaj zog nrog kev hnav zoo. Raws li kev siv ib txwm siv, nws tuaj yeem siv rau 3 mus rau 6 lub hlis lossis ntev dua. Lub neej tshwj xeeb nyob ntawm qhov zaus ntawm kev siv thiab cov khoom siv ntawm lub workpiece.

Q: Puas yog cov khoom siv nrov nrov? Puas yog nws tsim nyog rau kev siv hauv chaw ua haujlwm lossis chav kuaj?

A: Cov khoom siv tsis muaj suab nrov thaum lub sijhawm ua haujlwm, feem ntau <65dB, uas yog tsim rau siv hauv chaw ua haujlwm, chav kuaj, thiab kev cob qhia precision, thiab tsis cuam tshuam rau kev ua haujlwm ib puag ncig.

Q: Yuav ua li cas tswj thiab tswj nws?

A: - Ntxuav lub tank ua haujlwm tom qab txhua qhov siv los tiv thaiv cov khoom seem;

- Txheeb xyuas qhov hnav ntawm rab koob sib nqus tsis tu ncua;

- Txheeb xyuas lub cev muaj zog, inverter, thiab kab txuas txhua lub hlis kom pom tias lawv zoo li qub;

- Khaws lub tshuab kom qhuav thiab tso cua kom tsis txhob muaj dej vapor corrosion ntawm cov khoom siv hluav taws xob.