Handheld Laser Vuam Tshuab

Nqe lus piav qhia luv luv

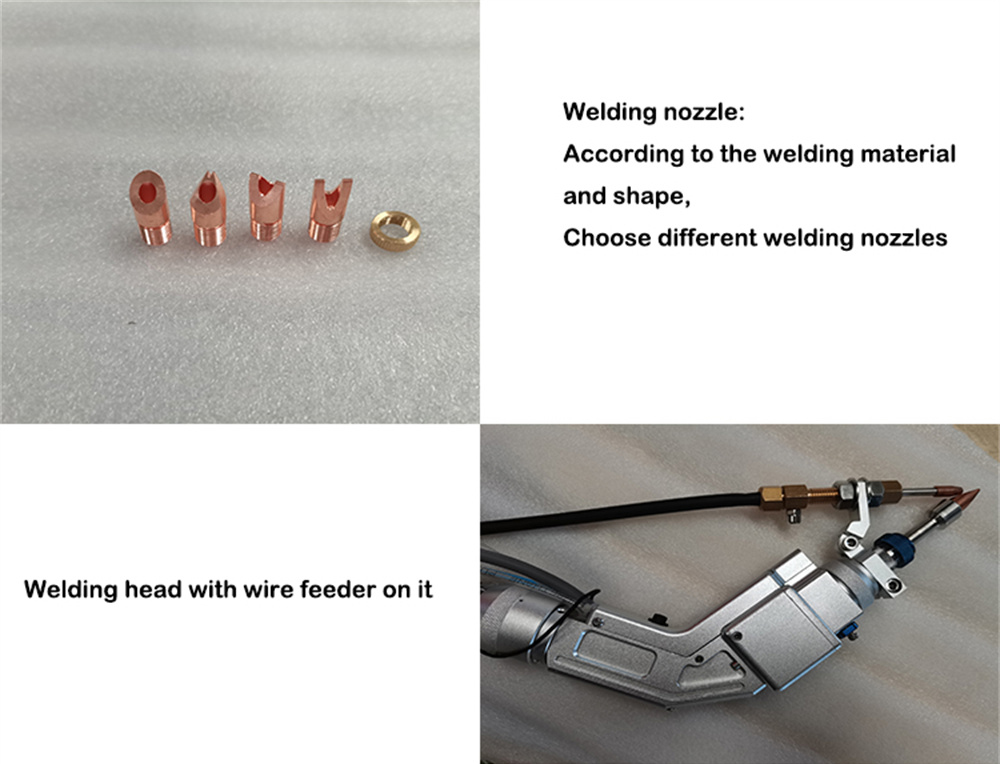

- Muaj 6 hom vuam thiab ntau qhov vuam nozzles kom tau raws li qhov sib txawv vuam xav tau; nws muaj kev ruaj ntseg sensor muaj nuj nqi, uas emits lub laser tom qab kov cov hlau thiab cia li xauv lub teeb thaum nws raug tshem tawm.

- Lub tshuab yog nruab nrog tsis siv neeg hlau- feeder ntaus ntawv, uas tuaj yeem kho qhov tsis zoo thiab muab ntau yam kev xaiv rau

cov neeg siv khoom.

- Muaj 6 hom vuam thiab ntau qhov vuam nozzles kom tau raws li qhov sib txawv vuam xav tau; nws muaj kev ruaj ntseg sensor muaj nuj nqi, uas emits lub laser tom qab kov cov hlau thiab cia li xauv lub teeb thaum nws raug tshem tawm.

- Dual kub thiab dual tswj, circulating dej Circuit Court, tuaj yeem txias cov kav dej sab hauv ntawm lub vuam taub hau, thaum txias lub laser.

Khoom Qhia

Technical parameter

| Qhov xwm txheej | Tshiab | Cov ntsiab lus tseem ceeb | Laser Source |

| Kev siv | Weld Hlau | Max. Tso zis zog | 2000 W |

| Khoom siv tau | Hlau | Cnc los yog Tsis | Yog lawm |

| Txias hom | Dej Txias | Tswj Software | Ruida/Qilin |

| Pulse Dav | 50-30000Hz | Laser zog | 1000w / 1500w / 2000w |

| Qhov hnyav (Kg) | 300 Kg | Daim ntawv pov thawj | Ce, Iso 9001 |

| Cov ntsiab lus tseem ceeb | Fiber Laser Source, Fiber, Kov Laser Vuam taub hau | Ntsiab Muag Khoom | High-Accuracy |

| Muaj nuj nqi | Hlau Part Laser Vuam | Fiber Length | ≥10m |

| Siv Tau Kev Lag Luam | Chaw ntiav pw, khw muag khaub ncaws, tsev muag khoom siv | Cov ntsiab lus tseem ceeb | Laser khoom |

| Hom Kev Ua Haujlwm | Pulsed | Tom qab Warranty Service | Kev them nyiaj yug online |

| Focal Spot Diameter | 50m ua | Lub wavelength | 1080 ± 3nm |

| Video Kev Tshuaj Ntsuam Xyuas | Muab | Graphic Format txaus siab | Ai, Plt, Dxf, Dwg, Dxp |

| Qhov Chaw Keeb Kwm | Jinan, Shandong xeev | Lub Sijhawm Warranty | 3 Xyoo |

Main Parts rau Tshuab

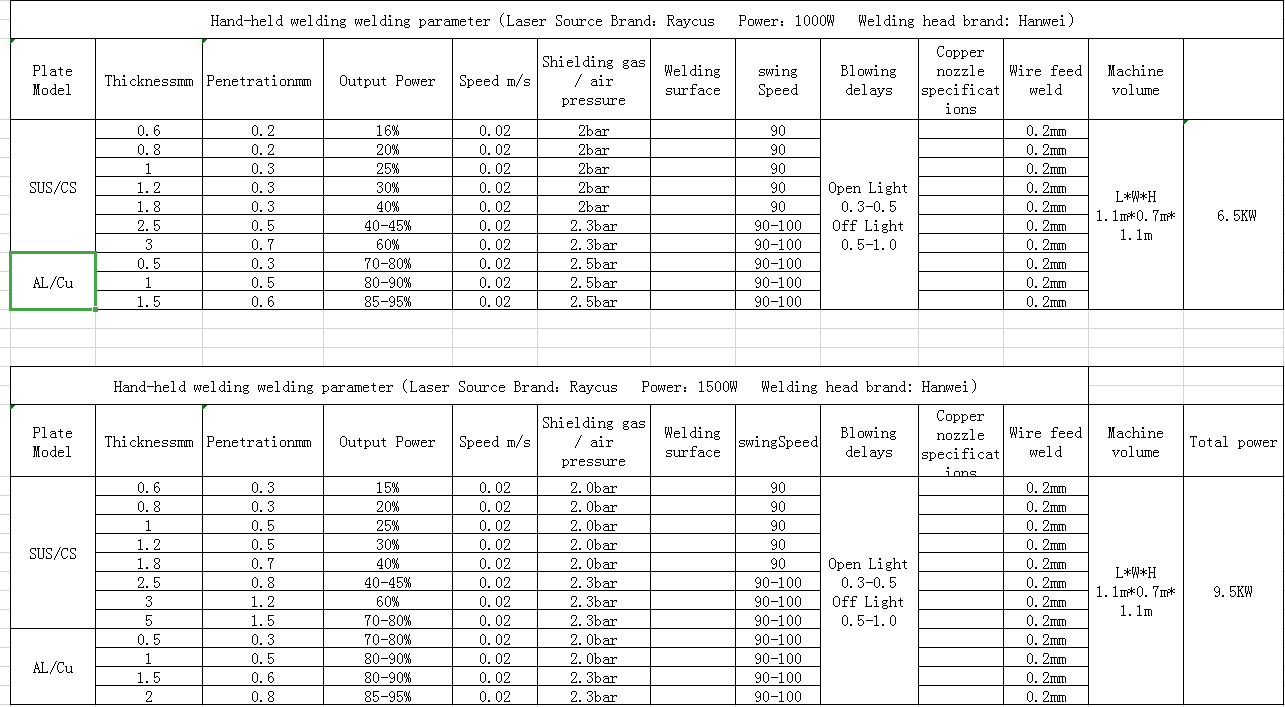

Vuam parameter rau laser vuam tshuab

Kev teeb tsa

| Laser zog | 1000 wb | 1500 W | 2000 W | ||||||

| Vuam Khoom | Stainless hlau | Carbon Steel | Aluminium | Stainless hlau | Carbon Steel | Aluminium | Stainless hlau | Carbon Steel | Aluminium |

| Vuam Thickness (Mm) | 2 | 2 | 1 | 3 | 3 | 2 | 4 | 4 | 3 |

| Vuam Thickness (Inch) |

|

|

|

|

|

|

|

|

|

| Adaptable Vuam Hlau | Vuam hlau txoj kab uas hla 0.8-1.6mm | ||||||||

| Weld Seam Requirement | Filler Hlau Vuam ≤1Mm Viav Vuam ≤15% Ntawm Phaj Thickness≤0.3Mm | ||||||||

| Tshuab hnyav | 220 Kg | 220 Kg | 300 Kg | ||||||

| Tshuab Loj (Mm) | 954x715x1080 ua | 954x715x1080 ua | 1155X715X1160 | ||||||

| Vuam Phom Kab Length | 10m (Lub Hlau Pub Tube Ntawm Cov Hlau Feeder Yog 3 Meters Ntev) | ||||||||

| Weld Phom Nyhav | Vibrating Daim iav Hom (Qi Lin): 0.9Kg | ||||||||

| Tshuab fais fab | 7 kwv | 9 kwv | 12 kwv | ||||||

| Lus txhawb | Txuj: Suav, Askiv, Kauslim Teb, Nyab Laj, Lavxias Japanese thiab Spanish tuaj yeem hloov kho | ||||||||

| Voltage Thiab Zaus | Standard: 380V / 50Hz Lwm yam Voltage Thiab zaus yog xaiv tau | ||||||||

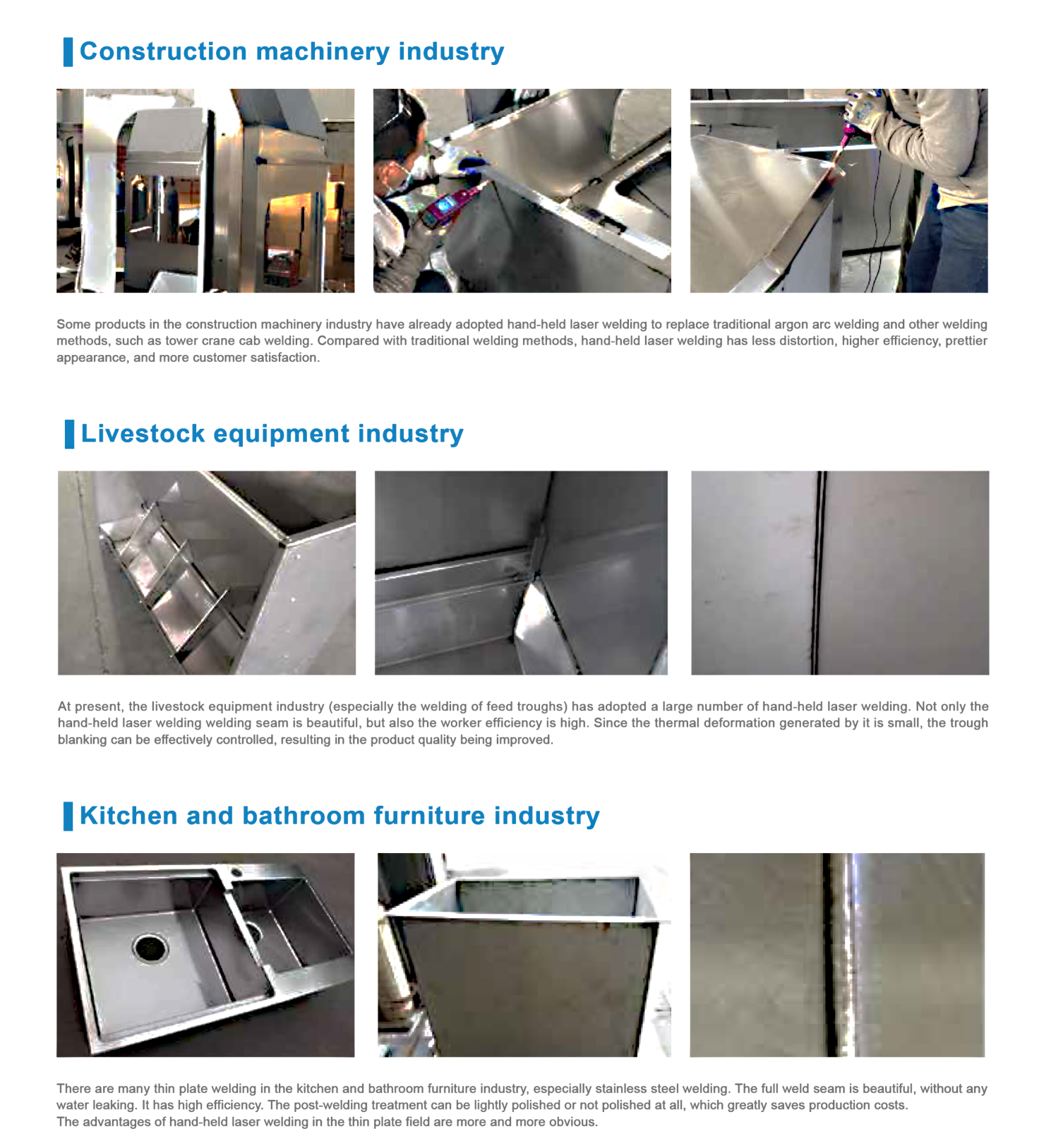

Daim ntawv thov kev lag luam

Laser vuam tshuab yog dav siv nyob rau hauv chav dej kev lag luam: vuam cov yeeb nkab dej sib txuas, txo cov pob qij txha, tees, li qub, thiab da dej. Kev lag luam tsom iav: precision vuam ntawm stainless hlau, titanium alloy thiab lwm yam ntaub ntawv ntawm lub buckle txoj hauj lwm, txheej thav duab thiab lwm txoj hauj lwm ntawm iav. Kev lag luam kho vajtse: impeller, kettle, kov, thiab lwm yam., welding ntawm complex stamping qhov chaw thiab casting qhov chaw. Laser vuam tshuab tau dav siv nyob rau hauv kev lag luam tsheb: cav lub tog raj kheej gaskets, hydraulic tappet foob vuam, spark plug vuam, lim vuam, thiab lwm yam.

Qhov zoo ntawm laser vuam tshuab

1. Kev siv dav dav: Lub tes tuav lub taub hau vuam yog nruab nrog 5m-10m thawj cov khoom siv kho qhov muag, uas kov yeej qhov kev txwv ntawm qhov chaw ua haujlwm thiab tuaj yeem siv rau kev vuam sab nraum zoov thiab kev sib txuas ntev;

2. Yooj yim thiab hloov tau yooj yim rau kev siv: Tes tuav laser vuam yog nruab nrog txav pulleys, uas yooj yim los tuav, thiab tuaj yeem hloov kho txhua lub sijhawm, tsis tas yuav tsum muaj qhov chaw ruaj khov, dawb thiab hloov tau, thiab haum rau ntau qhov chaw ua haujlwm.

3. Ntau txoj kev vuam: vuam ntawm txhua lub kaum ntse ntse tuaj yeem pom tau: stitch welding, taub qab vuam, ntsug vuam, tiaj tiaj vuam, sab hauv fillet vuam, txheej fillet vuam, thiab lwm yam. Vuam ntawm txhua lub kaum ntse ntse tuaj yeem ua tiav. Tsis tas li ntawd, nws tseem tuaj yeem ua tiav qhov txiav, vuam thiab txiav tuaj yeem hloov pauv dawb, tsuas yog hloov cov vuam tooj liab nozzle rau txiav tooj liab nozzle, uas yooj yim heev.

4. Cov nyhuv vuam zoo: tes tuav laser vuam yog kub fusion vuam. Piv nrog cov tsoos welding, laser welding muaj zog dua qhov ceev thiab tuaj yeem ua tiav cov txiaj ntsig zoo dua. Cov kab teeb meem, qhov tob vuam loj, txaus melting, ruaj khov thiab txhim khu kev qha, thiab lub zog vuam ncav cuag lossis txawm tias dhau ntawm lub hauv paus hlau nws tus kheej, uas tsis tuaj yeem lav tau los ntawm cov tshuab vuam zoo tib yam.

5. Vuam seam tsis tas yuav polished: Tom qab ib txwm welding, lub vuam taw tes yuav tsum tau polished los xyuas kom meej smoothness thiab tsis roughness. Lub tes tuav laser vuam tsuas yog qhia txog qhov zoo ntawm kev ua haujlwm: txuas txuas txuas, du tsis muaj ntses nplai, zoo nkauj tsis muaj caws pliav, thiab cov txheej txheem sib tsoo tsawg dua.

6. Tsis muaj cov khoom siv rau kev siv vuam: Hauv cov neeg feem ntau cov kev xav, kev ua haujlwm vuam yog "cov tsom iav ntawm sab laug tes thiab vuam hlau ntawm sab tes xis". Txawm li cas los xij, nrog lub tes tuav laser vuam tshuab, vuam tuaj yeem ua tiav yooj yim, thiab cov khoom siv hauv kev tsim khoom thiab kev ua haujlwm raug txo.

7. Nrog rau ntau yam kev ceeb toom kev nyab xeeb, lub vuam taub hau tsuas yog siv tau thaum lub hloov pauv yog kov thaum nws kov cov hlau, thiab lub teeb yuav raug kaw tom qab lub workpiece raug tshem tawm, thiab qhov kov hloov pauv muaj lub cev kub sensor. Kev nyab xeeb siab, ua kom muaj kev nyab xeeb ntawm cov neeg ua haujlwm thaum ua haujlwm.

8. Txuag tus nqi zog: Piv nrog arc vuam, tus nqi ua haujlwm tuaj yeem txo tau li ntawm 30%. Kev ua haujlwm yog qhov yooj yim thiab yooj yim rau kev kawm thiab kev kawm ceev, thiab cov txheej txheem ntawm tus neeg teb xov tooj tsis siab. Cov neeg ua haujlwm ib txwm tuaj yeem ua haujlwm tom qab kev cob qhia luv luv, thiab tuaj yeem ua tiav cov txiaj ntsig zoo vuam zoo.