Ib .Production Introduction:

JCZ dual-axis loj-hom splicing siv JCZ dual-extended axis tswj pawg thawj coj saib kom ua tiav cov cim kos cim dhau ntawm daim iav teb. Nws raug nquahu kom siv hom ntawv saum toj no 300 * 300, vim hais tias cov hom loj yog ua tiav los ntawm cov iav me me splicing thiab kos npe, yog li muaj qhov zoo ntawm lub teeb siv lub teeb, sib sib zog nqus cim qhov tob, thiab lwm yam, thiab qhov yooj yim tsom, tab sis nws yuav tsum muaj kev siv tshuab siab, yog li cov txheej txheem debugging yog cumbersome.

二 .Machine installation:

Vim tias qee qhov yuav raug tshem tawm thaum lub sijhawm xa khoom, koj yuav tsum tau nruab lawv tus kheej tom qab tau txais lub tshuab. Dab tsi koj yuav tsum tau nruab muaj xws li kab ke thiab txoj kev kho qhov muag. Rau txoj kev teeb tsa, xa mus rau lub tshuab kos npe zoo tib yam.

ḉ. Kev xeem khiav:

Tom qab tag nrho cov khoom siv tau teeb tsa, yuav tsum muaj ib qho kev sim ua haujlwm yooj yim, suav nrog lub teeb emissions thiab kev ntsuas txav ntawm txhua axis.

1.Khiav kev xeem:

Tom qab kev teeb tsa, thawj kauj ruam yog niaj hnub debugging xws li kev kuaj lub teeb thiab kev hloov pauv hloov.

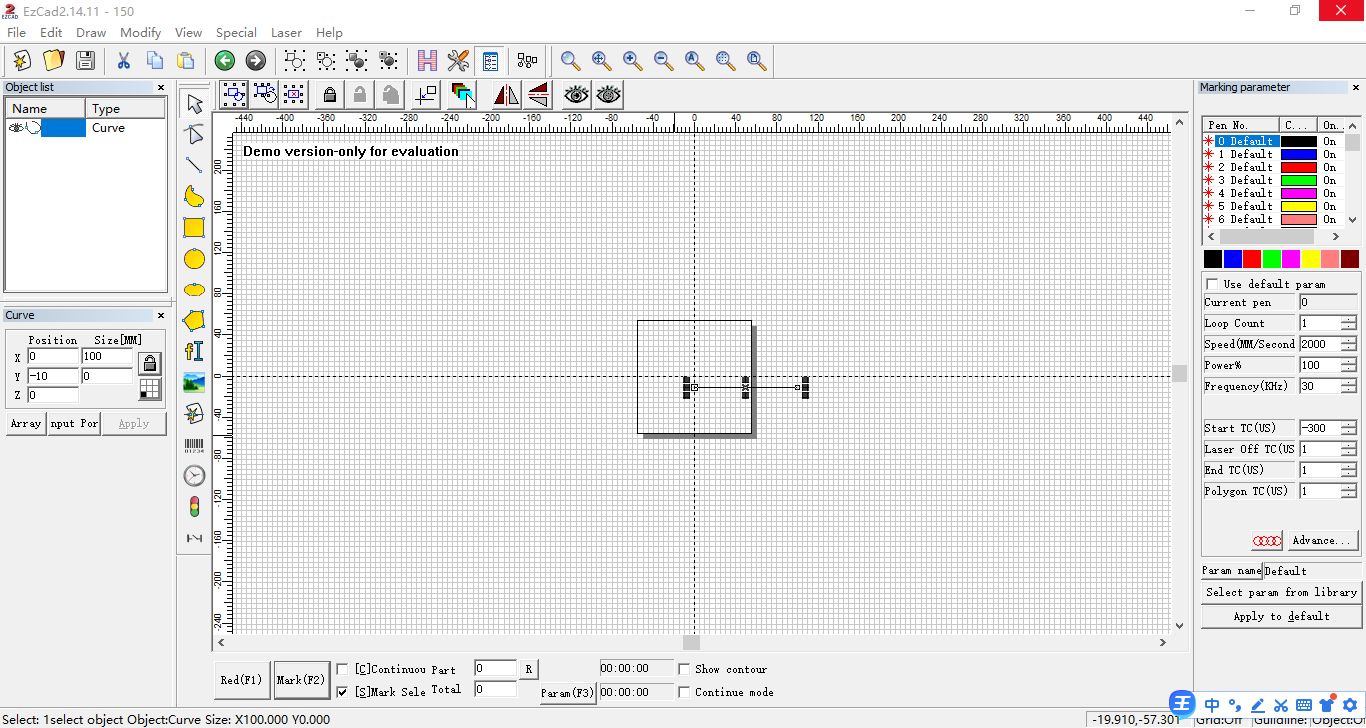

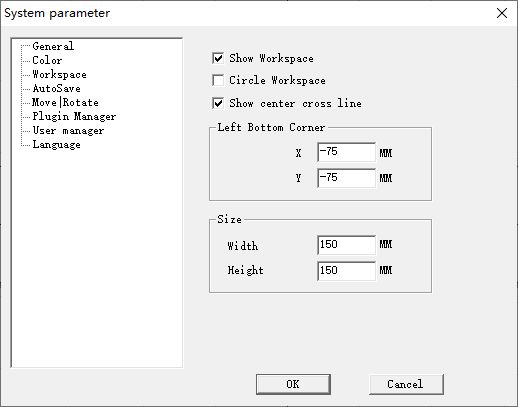

Sau nyob rau hauv txoj hauj lwm ntawm qhov chaw nruab nrab thiab qhov loj me raws li qhov loj ntawm lub teb lo ntsiab muag. Nyem rau ntawm qhov tsis nyob hauv qab ntawm tus qauv interface, thiab sau rau hauv raws li qhov loj ntawm lub teb lo ntsiab muag.

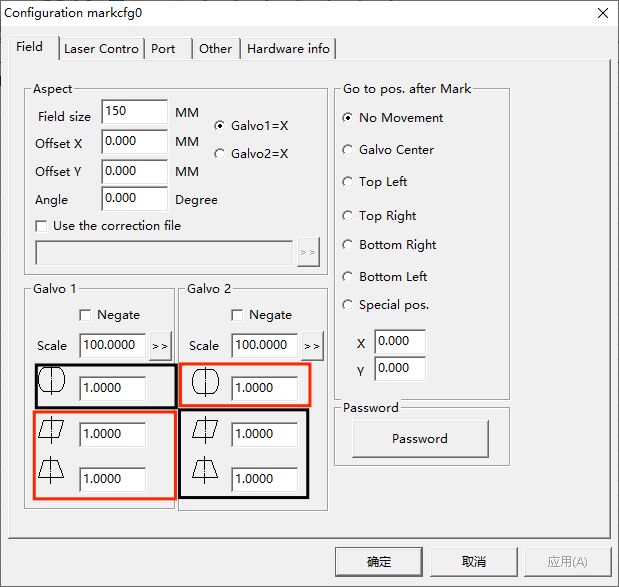

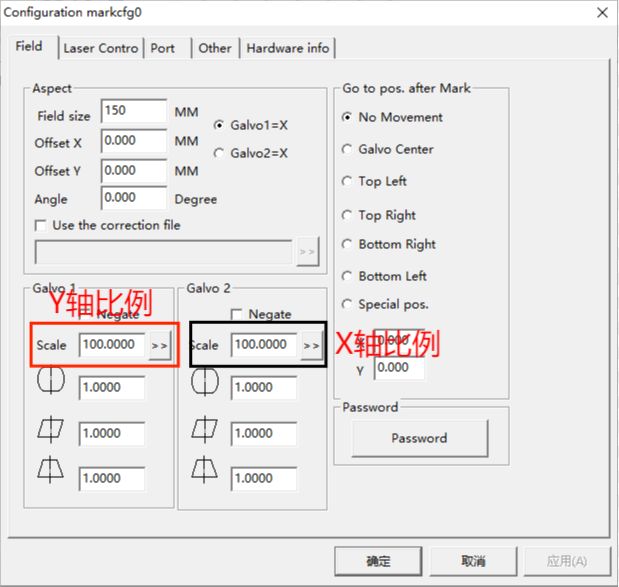

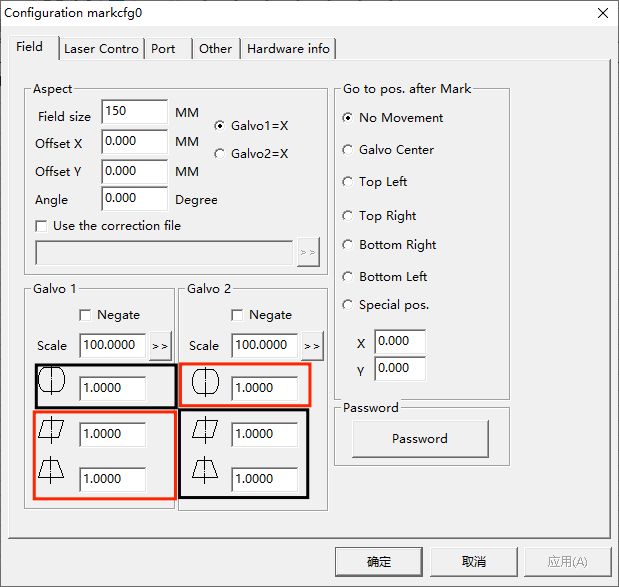

Scale kho, khij lub npov loj tshaj plaws raws li cov cim cim, thiab tom qab ntawd kos nws. Tom qab ntsuas, sau rau hauv qhov sib thooj ntsuas raws li qhov ntsuas qhov tseeb. Piv txwv li, X axis yog 150 hli, thiab qhov tseeb ntsuas yog 152 hli. Sau rau hauv daim duab hauv qab no, thiab Y axis yog tib qho laj thawj kom txog thaum nws pom zoo.

Tom qab ntawd sau cov kev kho tsis raug raws li qhov ntsuas qhov tseeb square deformation piv, raws li qhia hauv daim duab, Y-axis deformation tsis nyob hauv lub thawv liab, thiab X-axis deformation tsis nyob hauv lub thawv dub.

Lub cim thav duab yog ib lub xwmfab, tsis muaj deformation thiab tsis muaj kev xav txog ntug.

2. Kho ob axis:

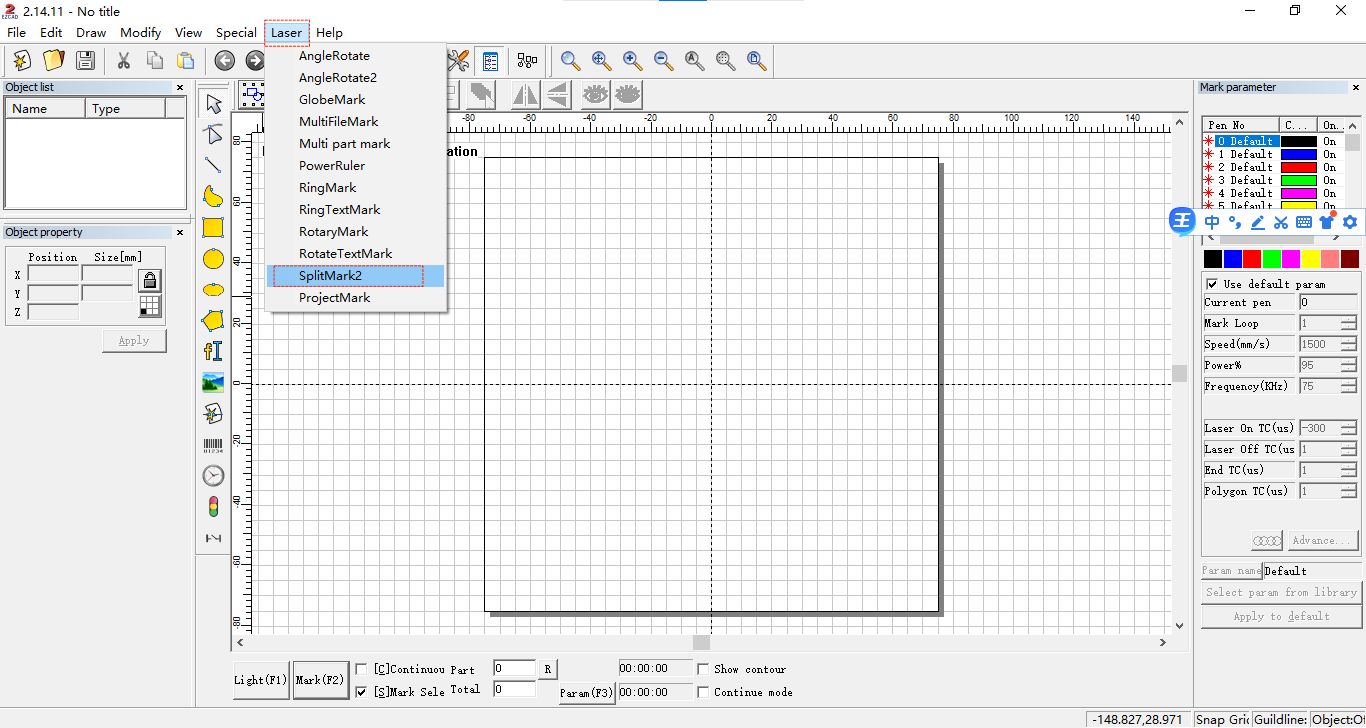

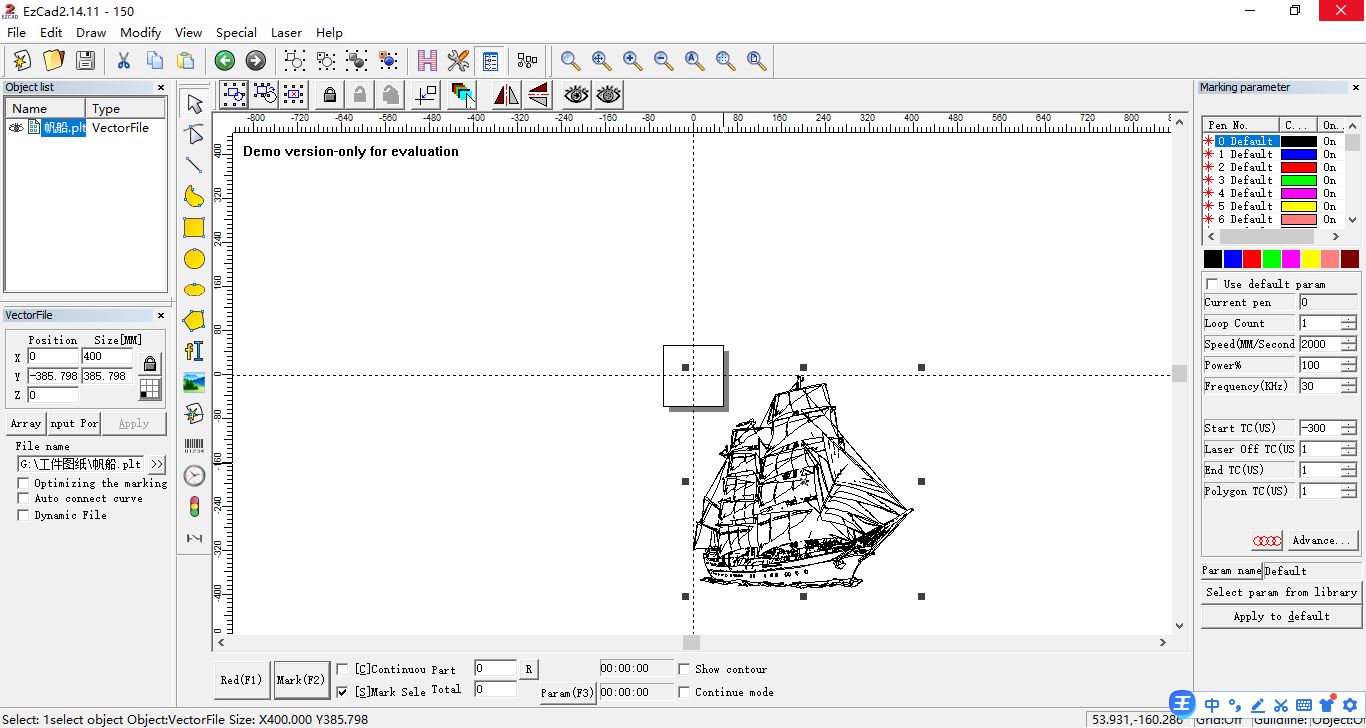

Nyob rau sab saum toj ntawm software, xaiv Laser -SplitMark2 nkag mus rau nplooj ntawv ua haujlwm SplitMark.

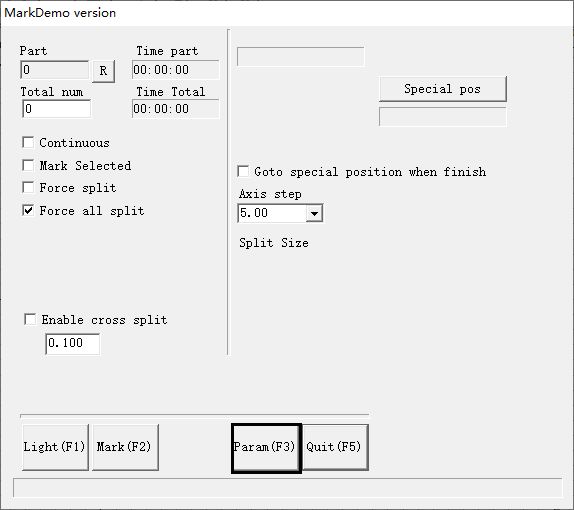

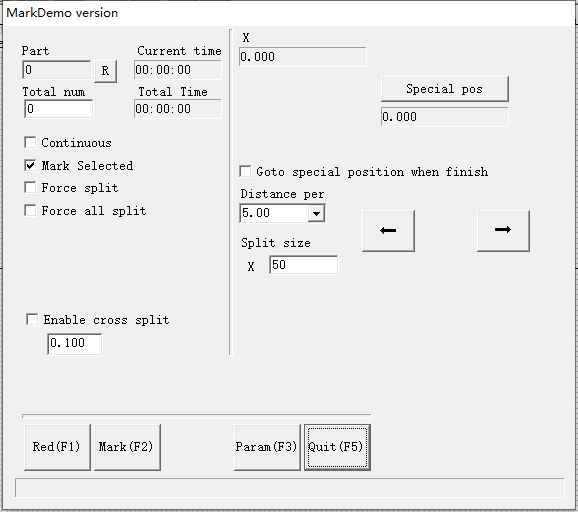

Nov yog SplitMark nplooj ntawv ua haujlwm. Tam sim no ob lub axes sab nraud tsis tau qhib. Nyem "F3" hauv qab no kom nkag mus rau qhov chaw sab nraud.

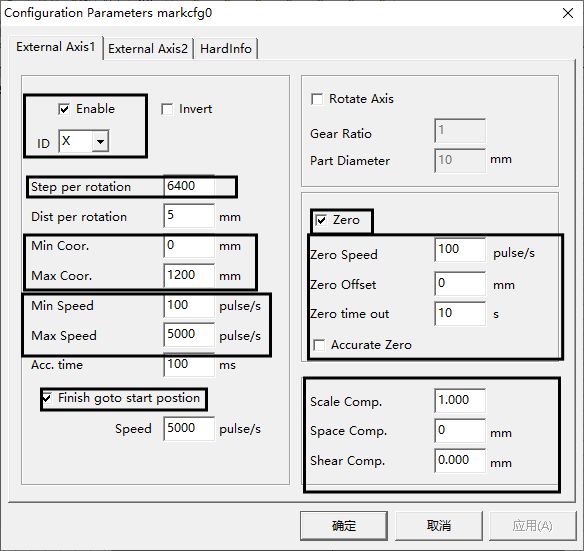

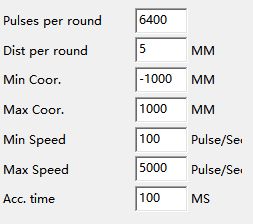

Ua piv txwv X sab nraud. Tom qab qhib, koj yuav tsum xyuas lub pob qhib, xaiv X raws li tus ID, thiab sau rau hauv Pulses ib puag ncig hauv qab no kom phim qhov tseeb lub cev muaj zog teeb tsa, txwv tsis pub yuav muaj teeb meem xws li cov kauj ruam ploj lossis tsis txaus txav deb. Qhov tsawg kawg nkaus Coor yog 0, thiab qhov siab tshaj plaws nyob deb tau sau raws li qhov loj ntawm lub tshuab.

Zero teeb muaj peb lub xeev, Qhov no yog pem hauv ntej xoom rov qab, tom qab xoom taw tes tau teeb tsa, cov kev taw qhia rov qab mus rau xoom taw tes rau pem hauv ntej., Lub xeev no yog lub xeev ntawm thim rov qab xoom rov qab. Tom qab teeb tsa xoom taw tes, lub cev muaj zog thim rov qab mus rau xoom taw tes., Hauv lub xeev no, tsis muaj xoom taw tes, thiab lub cev muaj zog tsis rov qab mus rau xoom.

Tom qab teeb tsa xoom rov qab kev taw qhia ntawm txhua axis kom raug, nws yog ib qho tsim nyog los ntsuas qhov tseeb ntawm txhua axis. Txoj kev calibration yog kos ib txoj kab ncaj nraim ntawm 100mm, 200mm, thiab 300mm, thiab tom qab ntawd ua cov cim cais, ntsuas cov kab kos tom qab kos, thiab sib piv cov txiaj ntsig. , raws li qhov tseeb teev, kho Dist ib puag ncig kom txog rau thaum kho

lub hom phiaj ntev yog zoo ib yam nrog lub cim ntev.

Tom qab cov kauj ruam nrug tau kho, cov nyhuv stitching yuav tsum tau kho. Tseem kos kab kab rov tav nrog qhov ntev ntawm 100mm, thiab tso cov kab hauv qab sab xis ntawm tag nrho cov haujlwm ua haujlwm.

Tom qab ntawd nyem SplitMark, Teem lub cim cais loj, teeb tsa rau 30mm, pib kos npe, thiab xyuas cov nyhuv.

Yog hais tias cov nyhuv splicing yog raws li qhia nyob rau hauv daim duab, nws txhais tau hais tias lub teb lo ntsiab muag tsis nyob rau tib lub sij hawm rau lub X-axis, thiab lub kaum sab xis ntawm lub galvanometer los yog X-axis yuav tsum tau kho kom txog rau thaum lub interface yog tiaj tus. Tib yam muaj tseeb rau kev hloov kho Y-axis. Yog tias lub galvanometer tau hloov kho kom sib npaug rau X-axis ua ntej, thiab tom qab ntawd qhov teeb meem no tshwm sim thaum lub sij hawm hloov ntawm Y-axis, koj yuav tsum tau kho qhov perpendicularity ntawm X-axis thiab Y-axis kom txog thaum kev hloov kho tiav.

3.Marking pib:

Tom qab kho cov nyhuv splicing, koj tuaj yeem pib kos npe. Kev kos npe yuav tsum tau muab cov qauv tso rau hauv lub kaum sab xis sab xis ntawm qhov chaw ua haujlwm. Raws li pom nyob rau hauv daim duab, thiab qhov ntau ntawm daim duab tsis tshaj qhov xoom taw tes thiab qhov siab tshaj plaws ntawm XY axis.

Tom qab tso daim duab, nyem SplitMark2, thiab tom qab teeb tsa qhov loj me, koj tuaj yeem pib kos.

Yog hais tias qhov teeb meem stitching tshwm sim dua thaum lub sij hawm kos npe, thov rov ua cov haujlwm saum toj no.

Post lub sij hawm: Feb-23-2023