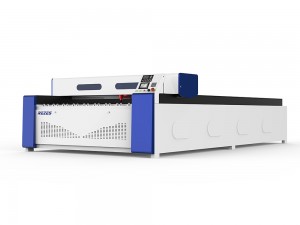

Peb hauv Ib Lub Tshuab Laser Vuam

Khoom Qhia

Technical parameter

| Daim ntawv thov | Laser vuam txiav thiab tu | Khoom siv tau | Cov khoom siv hlau |

| Laser Source Brand | Raycus/MAX/BWT | CNC los tsis | Yog lawm |

| Pulse Dav | 50-30000Hz | Focal Spot Diameter | 50m ua |

| Tso zis zog | 1500W / 2000W / 3000W | Tswj Software | Ruida/Qilin |

| Fiber Length | ≥10m | Lub wavelength | 1080 ± 3nm |

| Daim ntawv pov thawj | CE, ISO9001 | Txias qhov system | Dej txias |

| Hom kev ua haujlwm | Tsis tu ncua | Feature | Kev saib xyuas tsawg |

| Machinery Test Report | Muab | Kev tshuaj xyuas video tawm | Muab |

| Qhov Chaw Keeb Kwm | Jinan, Shandong xeev | Lub sijhawm lav | 3 xyoo |

Tshuab Video

Cov yam ntxwv ntawm Peb hauv Ib Lub Tshuab Laser Vuam

1. High zog ceev thiab siab vuam zog

Lub laser beam zog ceev ntawm lub nruam fiber ntau laser vuam tshuab yog siab heev, uas yuav sai sai yaj cov ntaub ntawv hlau thiab tsim ib tug khoom weld. Lub zog vuam tuaj yeem sib npaug los yog siab dua li ntawm cov khoom siv niam txiv.

2. Zoo nkauj welds, tsis tas yuav tsum tau ua tom qab

Cov welds uas tsim los ntawm laser vuam yog du thiab zoo ib yam, tsis muaj kev sib tsoo ntxiv los yog polishing, uas zoo heev txo tus nqi ntawm kev ua haujlwm tom qab. Nws yog tshwj xeeb tshaj yog haum rau kev lag luam nrog cov kev xav tau siab rau vuam zoo li cov khoom siv hlau stainless, hlau kho kom zoo nkauj kev lag luam, thiab lwm yam.

3. Ceev vuam ceev thiab txhim kho kev tsim khoom

Piv nrog rau cov txheej txheem vuam tsoos (xws li TIG / MIG vuam), qhov ceev ntawm cov tshuab fiber ntau txuas ntxiv tuaj yeem nce 2-10 zaug, txhim kho kev ua haujlwm zoo, thiab tsim nyog rau cov xwm txheej ntau lawm.

4. Me me tshav kub-tshem tawm tsam thiab me me deformation

Vim lub tsom xam cov yam ntxwv ntawm lub laser, lub tshav kub input nyob rau hauv lub vuam cheeb tsam yog me me, txo lub thermal deformation ntawm lub workpiece, tshwj xeeb tshaj yog haum rau vuam precision qhov chaw, xws li hluav taws xob Cheebtsam, kho mob, thiab lwm yam.

5. tuaj yeem vuam ntau yam khoom siv hlau, nrog rau ntau yam kev siv

Muaj feem xyuam rau cov hlau tsis muaj steel, carbon steel, aluminium alloy, tooj liab, npib tsib xee alloy, titanium alloy thiab lwm yam hlau thiab lawv cov alloys, dav siv hauv tsheb tsim, ntawv hlau ua, aerospace, khoom siv hluav taws xob, khoom siv kho mob thiab lwm yam lag luam.

6. High degree ntawm automation, tuaj yeem ua ke nrog cov neeg hlau vuam

Nruam fiber ntau laser vuam tshuab tuaj yeem ua ke nrog cov neeg hlau thiab CNC tshuab kom ua tiav cov vuam vuam, txhim kho qib kev tsim khoom ntse, txo cov kev cuam tshuam ntawm phau ntawv, thiab txhim kho cov khoom sib xws thiab ruaj khov.

7. Kev ua haujlwm yooj yim thiab tus nqi kho mob tsawg

Cov cuab yeej siv lub tshuab kov interface, kho tsis tau, thiab ua haujlwm yooj yim; fiber ntau laser muaj lub neej ntev (feem ntau mus txog 100,000 teev) thiab cov nqi kho mob qis, uas txo cov nqi siv rau kev lag luam.

8. Txhawb nqa tes thiab automated hom

Koj tuaj yeem xaiv lub taub hau vuam siv lub taub hau kom ua tiav cov vuam hloov tau yooj yim, uas yog tsim rau cov khoom loj lossis tsis sib xws; nws tseem tuaj yeem siv nrog lub tshuab ua haujlwm tsis siv neeg lossis cov neeg hlau kom tau raws li qhov xav tau ntawm kev sib dhos kab ntau lawm.

9. Ib puag ncig zoo thiab nyab xeeb, tsis muaj vuam slag, tsis muaj pa taws thiab plua plav

Piv nrog cov tsoos welding, laser vuam tsis tsim cov pa taws ntau, cov pa taws, thiab vuam slag, uas yog ib puag ncig zoo thiab nyab xeeb, thiab ua tau raws li cov qauv kev lag luam ntsuab niaj hnub.

Vuam qauv

Kev pabcuam

1. Cov kev pabcuam customized:

Peb muab customized fiber laser vuam tshuab, kev cai tsim thiab manufactured raws li cov neeg xav tau kev pab. Txawm hais tias nws yog vuam cov ntsiab lus, cov khoom siv lossis kev ua haujlwm nrawm, peb tuaj yeem kho thiab ua kom zoo raws li tus neeg siv khoom xav tau.

2. Kev sib tham ua ntej muag thiab kev txhawb nqa:

Peb muaj ib pab neeg ua haujlwm paub txog uas tuaj yeem muab cov neeg siv khoom nrog cov lus qhia ua ntej muag thiab kev txhawb nqa. Txawm hais tias nws yog kev xaiv cov cuab yeej siv, cov lus qhia hauv daim ntawv thov lossis kev qhia, peb tuaj yeem muab kev pab sai thiab ua tau zoo.

3. Cov lus teb sai tom qab muag

Muab kev txhawb nqa sai tom qab kev muag khoom los daws ntau yam teeb meem ntsib los ntawm cov neeg siv khoom thaum siv.

FAQ

Q: Cov ntaub ntawv dab tsi tuaj yeem welded los ntawm laser vuam tshuab?

A: Tsis tu ncua fiber ntau laser vuam tshuab yog tsim rau ntau yam khoom siv hlau, xws li: stainless hlau, carbon steel, aluminium alloy, tooj liab, npib tsib xee alloy, titanium alloy, galvanized ntawv, thiab lwm yam.

Rau cov hlau uas muaj kev cuam tshuam zoo heev (xws li tooj liab, txhuas), nws yog ib qho tsim nyog yuav tsum xaiv lub zog laser thiab vuam tsis zoo kom tau txais cov txiaj ntsig zoo vuam.

Q: Dab tsi yog qhov siab tshaj plaws vuam thickness ntawm laser vuam?

A: Lub vuam thickness nyob ntawm lub zog laser.

Q: Puas yog laser vuam yuav tsum tau shielding roj?

A: Yog lawm, kev tiv thaiv roj (argon, nitrogen lossis roj sib xyaw) feem ntau xav tau, thiab nws cov haujlwm suav nrog:

- Tiv thaiv oxidation thaum vuam thiab txhim kho vuam zoo

- Txo qhov tsim ntawm vuam porosity thiab txhim kho vuam lub zog

- Txhawb nqa lub pas dej molten solidification thiab ua rau cov weld smoother

Q: Dab tsi yog qhov txawv ntawm handheld laser vuam tshuab thiab tsis siv neeg laser vuam tshuab?

A: Handheld: Tsim nyog rau kev ua haujlwm yooj yim, tuaj yeem vuam cov duab tsis zoo thiab cov haujlwm loj, tsim rau cov khoom me me thiab nruab nrab.

Automation: Tsim nyog rau qhov loj-loj, qauv tsim, tuaj yeem sib xyaw cov caj npab thiab vuam chaw ua haujlwm txhawm rau txhim kho kev tsim khoom.

Q: Puas yuav deformation tshwm sim thaum laser vuam?

A: Piv nrog rau cov txheej txheem vuam tsoos, laser vuam muaj cov cua sov qis thiab cov cua sov me me, thiab feem ntau tsis ua kom pom tseeb deformation. Rau cov ntaub ntawv thinner, qhov tsis tuaj yeem hloov kho kom txo tau cov cua sov nkag thiab txo qis deformation ntxiv.

Q: Lub sijhawm ua haujlwm ntawm cov cuab yeej siv ntev npaum li cas?

A: Lub neej theoretical ntawm fiber ntau laser tuaj yeem ncav cuag "100,000 teev", tab sis lub neej tiag tiag nyob ntawm kev siv ib puag ncig thiab kev saib xyuas. Kev tswj kom txias zoo thiab tu cov khoom siv kho qhov muag tsis tu ncua tuaj yeem ua rau lub neej ntawm cov khoom siv.

Q: Cov teeb meem dab tsi yuav tsum tau them sai sai rau thaum yuav lub tshuab laser vuam?

A: - Paub meej tias qhov yuav tsum tau muaj cov khoom siv vuam thiab tuab, thiab xaiv lub zog tsim nyog

- Xav txog seb puas yuav tsum tau siv vuam tshuab los txhim kho kev tsim khoom

- Xaiv lub chaw tsim khoom txhim khu kev qha kom ntseeg tau cov khoom siv zoo thiab kev pab cuam tom qab muag

- Nkag siab seb puas yuav tsum muaj cov cua txias tshwj xeeb lossis kev tiv thaiv